By Mikko Syrjälä, Project Manager, Econet Oy

I’ve been working with wastewater treatment equipment for over a decade, and one thing I’ve learned is that even the most essential parts of the process often fly under the radar. Clarifiers are a perfect example. They do their job quietly in the background, but without them, you’d run into trouble fast.

So in this article, I want to explain in plain language what a clarifier actually is, how it works, and why it really matters whether you’re running a municipal plant or handling tough industrial flows.

What Is a Clarifier?

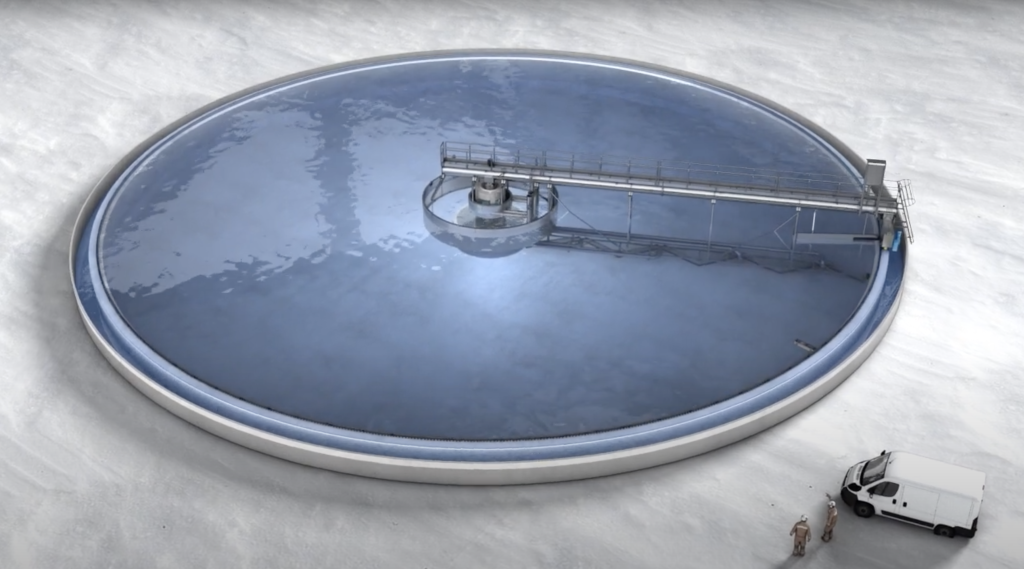

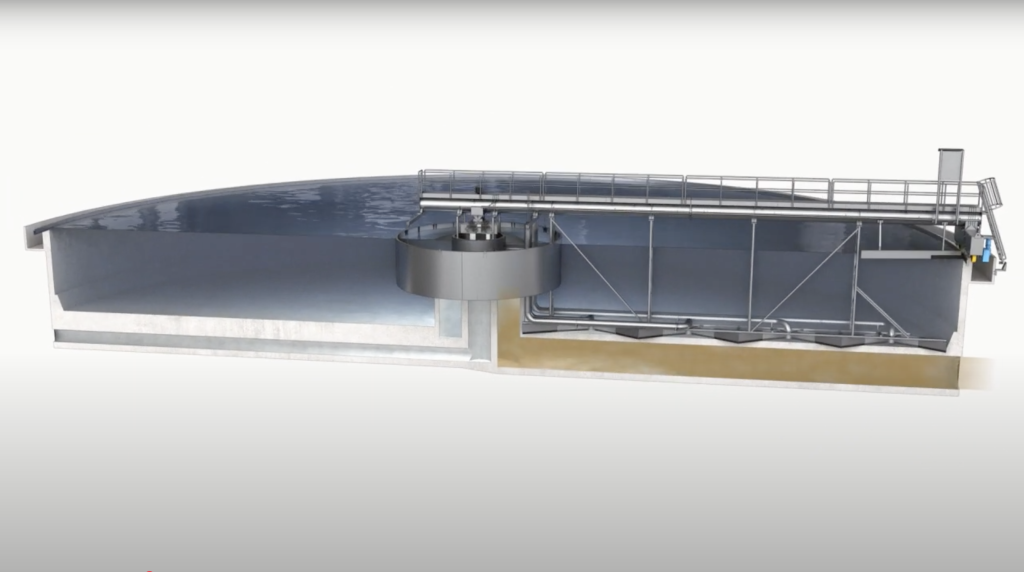

A clarifier is basically a settling tank. Water flows in, solids sink down, clean(er) water flows out. Simple? On the surface, yes. But getting it to work reliably day in and day out, especially in cold conditions or with varying sludge loads, is a bit more complicated.

You’ll usually find a clarifier at the beginning or end of a wastewater treatment process. Its job is to separate suspended solids like biological sludge, sand, or organic material. This is important not just for water quality but also to ensure the rest of the treatment system isn’t overloaded.

So, How Does a Clarifier Actually Work?

Here’s the basic idea:

- Incoming water flows slowly across the tank.

- Gravity pulls heavier particles down to the bottom.

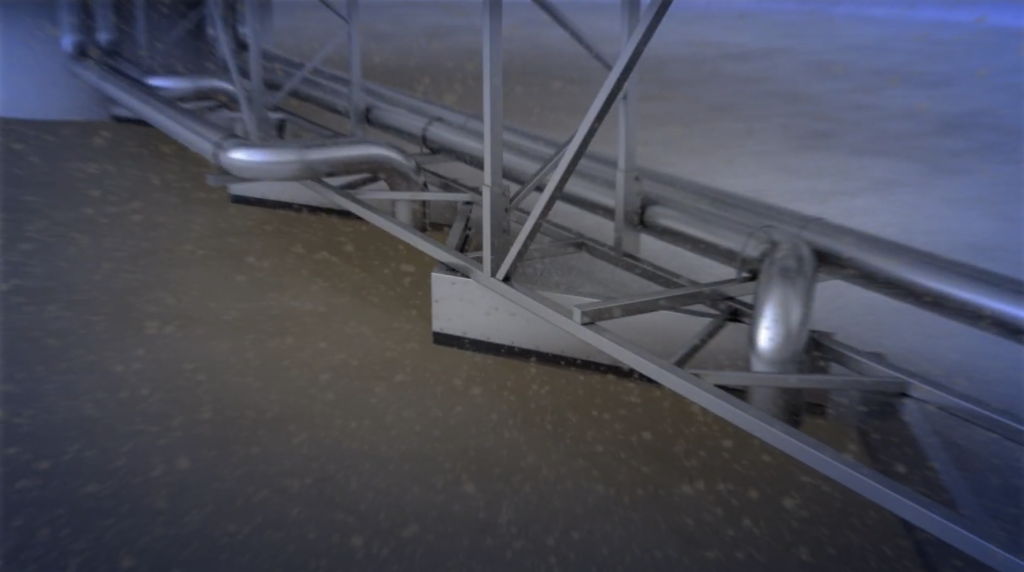

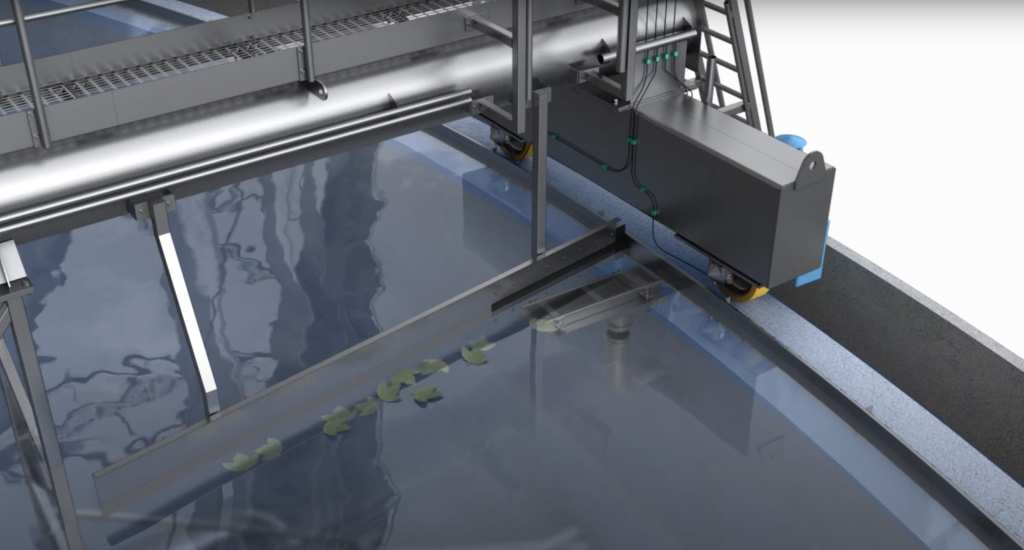

- Sludge is collected using scrapers or suction pipes.

- Clear water flows out over weirs or into channels for further treatment.

At Econet, we work with three types of clarifiers, and I’ve had my hands on all of them. Each one is built to suit different needs:

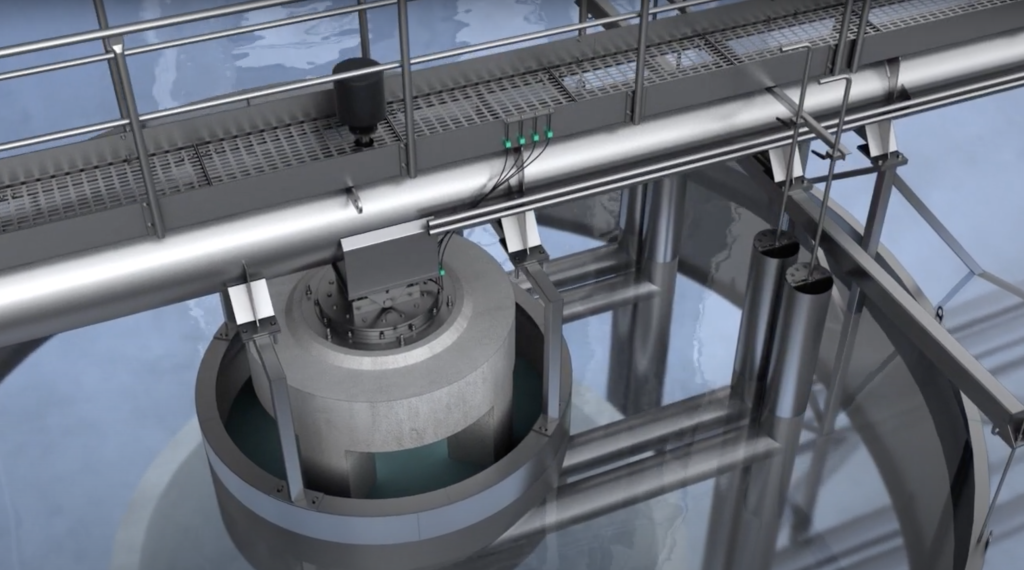

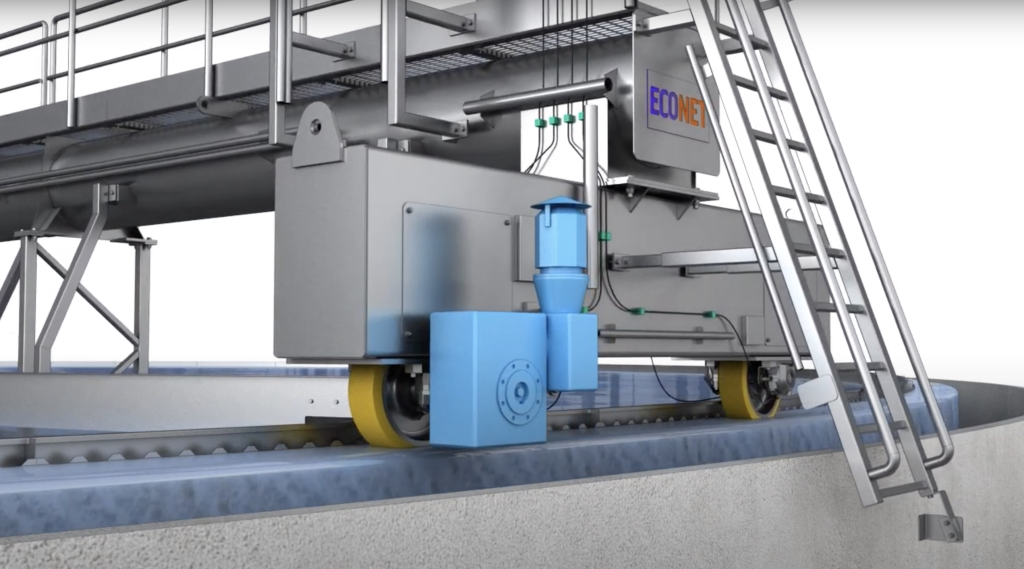

PI Suction Clarifier—A reliable workhorse, especially good for biological sludge. The suction system is based on the principle of communicating vessels. There are no parts underwater that require maintenance, and since the drive track is submerged, there’s no risk of it freezing during winter. A big plus in Nordic conditions.

PS-P Blade Scraper Clarifier—This is our heavy-duty option for industrial flows. It uses a multi-blade scraper to handle dense sludge without a fuss. Like the PI model, it has no maintainable components underwater. The drive track runs beneath the water surface, so you won’t run into freezing issues even in cold weather.

PS-S Spiral Scraper Clarifier—A lighter, energy-efficient model we recommend for applications with easily flowing sludge blankets. As with the others, the drive track is under the water surface, which keeps it safe from freezing in winter.

All of our clarifiers are built with reliability in mind. We design and supply both the process and the equipment, which means everything fits together from day one. No surprises later.

Why Bother? Here’s Why It Matters

When a clarifier is designed well and running smoothly, it makes life easier in more ways than one:

- Better water quality — Removes solids before they cause trouble downstream.

- Lower costs — You’ll save on chemicals, energy and maintenance.

- Environmental protection — Staying within discharge limits is simpler.

- Fewer headaches — A steady process is a predictable process.

From a project manager’s perspective, I can tell you that a solid clarifier setup is like a reliable colleague. You don’t think about it much because it just does what it’s supposed to do.

Our Approach at Econet

At Econet, we design complete water treatment solutions, so every clarifier we deliver is part of a bigger picture. Our systems are used across Finland and beyond, from Arctic municipal plants to demanding industrial projects.

We also support the full lifecycle, including design, delivery, spare parts, and keeping things running for the long haul.

Whether you’re after a suction clarifier or a robust blade scraper, we’ll make sure it’s the right fit for your process. And we’ll be here if you need us later.

In Summary

Clarifiers aren’t flashy, but they’re crucial. If you’re planning a new plant or looking to upgrade, don’t underestimate the benefits of the right clarifier for performance, reliability, and peace of mind.

Got questions? Want to chat through options? I’m happy to help.